Industrial clutches play a vital role in ensuring efficiency and reliability in heavy-duty machinery, and WPT Power is a trusted name in delivering exceptional performance. Known for their durability, precision, and innovative design, WPT Power’s clutches cater to a wide range of industrial applications. In this blog, we explore the key features, benefits, and industry-leading excellence of WPT Power’s industrial clutches.

Table of Contents

The Innovations Behind WPT Power’s Industrial Clutches: Engineering Marvels that Advance Performance

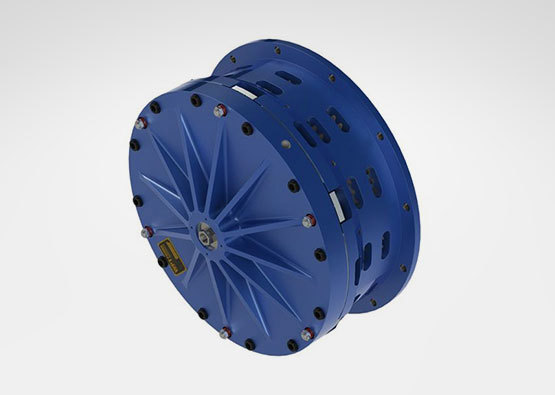

For decades, WPT Power has revolutionized industrial clutches from WPT Power with unparalleled innovation, quality construction, and proven dependability. At the vanguard of their engineering is a diligent dedication to progressing functionality while confronting the divergent demands of various sectors. Unlike commonplace clutches, WPT Power ingeniously combines sophisticated mechanisms with user-focused features. Consider the WPT clutch, which operates using a self-calibrating system enhancing efficiency and lengthening operational lifespan. Each customized clutch guarantees clients receive a product tailored to their exact needs. Moreover, WPT applies a holistic design approach, often integrating user feedback into products. This iterative process led to advancements such as the patented Over Torque Shut Off protecting machinery from overloads by decreasing downtime and associated costs. Such innovations represent not simply evolution but revolution in how industrial clutches from WPT Power are conceived, engineered, and fabricated. WPT Power is shaping the very future of industrial technology with a vision of unparalleled excellence resonating across industries, far beyond merely producing clutches.

Cutting-Edge Materials: Exploring the Science of Durability

The exceptional resilience and dependability of WPT Power’s industrial clutches arises substantially from the pioneering materials implemented in their construction. The manufacturers appreciate that clutches run under extreme situations where warmth, stress, and damage can appreciably impact performance. To mitigate these tests, WPT utilizes sophisticated materials such as robust alloy mixtures, composites, and highly specialized polymer blends that offer extraordinary thermal steadiness and resistance to deterioration. These materials are specially engineered to endure the corrosive environments present in industries like mining and farming, confirming that the clutches maintain their integrity through time. State-of-the-art fabrication procedures, including meticulous machining and temperature treatment, further strengthen the strength and toughness of the clutches. The outcome is a solution that not only acts productively under strain but also pledges a longer career, reducing the necessity for replacements or repairs and ensuring operational efficiency across numerous applications.

Real-World Applications: Where Innovation Collides with Commercial Needs

The remarkable flexibility of WPT Power’s industrial clutches has manifested across a diverse array of sectors—from forceful fabrication to agricultural machinery, and beyond. In manufacturing, WPT clutches are deployed in conveyor networks, where their robust architecture secures seamless cargo transport, significantly boosting efficiency. Moreover, in agricultural contexts, these clutches facilitate tractor and harvester functionality, enabling peak output even under duress. WPT Power clutches also dazzle in mining, where unrivaled performance under pressure proves critical. The inherent harshness of mining demands equipment that withstands constant usage without compromising capabilities. By incorporating WPT clutches, organizations can maximize productivity while minimizing downtime, essential for maintaining profit margins in competitive markets. The genuine versatility of these clutches underscores their innovative excellence and positions WPT as the leader in clutch technology.

Understanding the Mechanisms: How Industrial WPT Clutches Achieve Peak Performance

To fully appreciate the exceptional functionality of WPT Power’s clutches, one must comprehend the critical components that constitute these systems. A typical industrial WPT clutch contains several fundamental parts, including the housing shell, friction pads, springs, and input/output shafts. The housing shell acts as the structural backbone, securely holding all components in a protective casing. Friction pads, often fabricated from high-grip materials, are engineered to generate a frictional grip when engaged, seamlessly relaying power from the input to the output shaft. Springs serve a pivotal role in disengaging, allowing the clutch to smoothly release when necessary. The arrangement of these constituents achieves a delicate balance of mechanical engineering and applicable usefulness. For example, WPT’s precise design confirms that heat built up during operation is efficiently dispersed, preventing any possible harm from overheating. Understanding the anatomy of these clutches provides insight not just into how they function but also why they are trusted across diverse industries.

The Physics of Engagement: Every Turn Counts

The actions of any industrial clutch are fundamentally based on the intricacies of how it binds and separates. When initiating a WPT clutch, a multifaceted process begins relying on exactness of placement and the forces of adhesion and pressure. As the driving shaft revolves, the contact plates are pressed together, producing the necessary frictional strength to convey torque to the driven shaft. WPT clutch designs assure that stress applied during engagement is uniform, optimizing how might is shared. This delicate interplay not only facilitates smooth operation but also enhances overall efficiency. What’s more, developments like automatic calibration in WPT further ensure the engagement remains optimized under changing conditions, adding to dependability and performance. Understanding these physical rules permits users to value the engineering refinement within WPT Power clutches.

Comparative Analysis: WPT vs. Competitors

When contrasting WPT Drive industrial clutches against those of challengers, numerous notable contrasts emerge. Customization lies at the core of WPT’s offering, as they tailor each clutch to precisely accommodate client needs through an immense spectrum of dimensions and setups. This pliability allows end-users to choose a solution engineered for optimal performance within their specific application, driving operational excellence to new heights. Additionally, WPT’s ongoing materials research produces innovations that set them apart, as many rivals still depend on standard substances unable to withstand demanding conditions. In stark contrast, WPT spends extensively exploring and developing advanced materials offering lengthened lifespans and sturdiness. Moreover, WPT’s established record of robust after-sales help and maintenance cannot be overstated, as they form deep relationships maintaining equipment uptime, core to industries depending on consistency. In this contrasting landscape, WPT Drive’s industrial clutches undoubtedly stand out for quality, customization, and client commitment.

Industries Transformed: The Impact of WPT’s Clutch Solutions

The integration of WPT Power’s industrial clutches significantly enhances overall efficiency and productivity within manufacturing. By incorporating advanced clutch technology, facilities can dynamically configure operations, reducing delays and maximizing throughput. The ability to efficiently manage varying torque loads while consistently performing without excessive component wear is paramount to achieving objectives. For instance, WPT designs clutches to handle the fluctuating high-torque demands ubiquitous in manufacturing environments, such as machinery and material transport systems. These clutches seamlessly transfer products between assembly stages, moreover safeguarding against interruptions and inefficiencies resulting from overloads. Furthermore, the straightforward installation and upkeep offered by WPT clutches means plants can manufacture with minimal interruption, further elevating productivity. In an era where manufacturing must evolve to satisfy ever-growing demands for speed and efficiency, WPT Power emerges as an invaluable ally, supplying industries with the tools necessary to thrive in relentless global competition.

Agriculture: Powering Progress through Dependability

In agriculture, dependability and efficiency are crucial, and WPT Power’s industrial clutches provide precisely that. Agricultural machinery, from tractors to combines, operates under punishing conditions and substantial loads. WPT clutches are engineered to endure the rigors of farming contexts, ensuring consistent operation throughout cultivation seasons. These clutches not only enhance equipment dependability but also aid fuel efficiency, a chief concern in modern agricultural practices where expenditures are tightly managed. The premium friction materials and robust design make sure minimal energy is wasted, translating into substantial savings for farmers in the long term. In addition, WPT engages with agricultural partners to stay attuned to sector specifics, allowing for continuous advancement and refinement of clutch designs. As agriculture increasingly embraces innovative technologies, the role of sturdy and economical equipment remains unchanged. WPT Power leads this evolution, empowering farmers to maximize yields and streamline procedures through cutting-edge clutch solutions.

Mining Machinery’s Toughness Tested in Harsh Environments

Mining’s punishing settings require tools that function flawlessly under duress. WPT Power industrial clutches specially suit this area, where reliability isn’t negotiable. Operations frequently use heavy machinery handling not merely loads’ mass but also potential temperature variances and particle contamination. WPT clutches’ meticulous design keeps them running in these difficult conditions, bettering mining’s safety and productivity. For instance, self-detaching options ensure machines promptly release under strain, averting possible jams or damage. Additionally, WPT clutches’ rugged construction necessitates little servicing, allowing mines to prioritize output over maintenance. As mining faces new obstacles regarding efficiency and sustainability, WPT Power clutch solutions pave the path to not just continuing capabilities but also advancing environmentally-friendliness inside the sector.

Investing for the Future: The Economic Advantage of WPT Clutches

While an investment in WPT Power’s industrial clutches demands a higher upfront cost than competitors, it proves a strategic decision aimed at long-lasting profits. Though initially expensive, WPT products endure where others fail, reducing replacement needs and associated downtime fees. Their sturdy design and smooth operation minimize risk of malfunctions, shielding operations and earnings from disruptions’ rippling impacts. A subpar clutch breaking down risks more than repair bills—halted work means lost production and delayed projects percolating throughout the supply chain. WPT prioritizes quality, curbing complications to preserve companies’ bottom lines. As organizations grow savvier about expenditures, selecting WPT clutches’ strength proving itself in savings that surmount sticker shock, cementing their role as a prudent choice for a profitable future.

Maintenance Made Effortless: How to Maximize Lifespan

The longevity of WPT Power’s industrial clutches is enhanced not solely by their resilient architecture but too by the ease of preservation they offer. Understanding that routine care regimens are often overlooked can lead to premature equipment failure, WPT incorporates features intended to simplify upkeep. Regular preservation protocols for WPT clutches usually involve straightforward reviews of components like the friction plates and springs, which can be conducted with minimal interruption to operations. WPT also provides comprehensive guidelines and support, guaranteeing that users are well-informed on best practices. By adhering to these maintenance suggestions, businesses can significantly extend the operational lifetime of their clutches, optimize performance, and circumvent unnecessary repair costs. Moreover, the design philosophy behind WPT clutches accommodates accessibility for servicing, which is crucial in high-demand industries where time is invaluable. In this manner, WPT not only underscores the importance of maintenance but actively paves the way for simple implementation, reinforcing their commitment to client satisfaction and success.

Environmental Considerations: Sustainability in Engineering

As awareness grows of our impact on the natural world, the engineers at WPT Power take seriously their duty to lessen this impact. Both in sourcing materials and designing manufacturing processes that curb waste, eco-friendliness underpins production of their industrial clutches. WPT also strives to craft clutches that help reduce energy use throughout operational lifespans. Peak performance and efficiency benefit clients financially while also lowering their carbon footprints. By devising clutches offering enhanced function yet imposing less strain on resources, WPT Power leads as a company reconciling commercial needs with environmental stewardship. Furthermore, the sturdiness and longevity of WPT clutches mean less need for replacements and decreased material wastage in the long run. This commitment to sustainability resonates with forward-thinking firms seeking to harmonize with eco-conscious practices, confirming WPT as a partner of choice for industries aiming to thrive amid sustainability. In sum, the intersection of high-quality engineering, innovative structuring, and environmental concern positions WPT Power’s industrial clutches as a top pick for today’s rapidly evolving industrial landscape. As demand grows for efficiency and sustainability, WPT’s dedication to excellence will continue defining the norm in clutch technology.