Since none of us is going to be looking into Graphene to build a better battery or strengthen golf clubs, let’s look at the benefits of Graphene for detailing. As a coating, Graphene is best known to help with the issues of water spotting and staining. Some companies claiming no water spotting or etching with their Graphene products. This is where some companies begin to rely on hype to market Graphene. The unique structure of Graphene is what gives it the ability to reduce water spotting. Some companies that make Graphene coatings claim up to 50% less water spotting in comparison to ceramic coatings and this is more realistic than the marketing hype offered by some companies offering Graphene coatings.

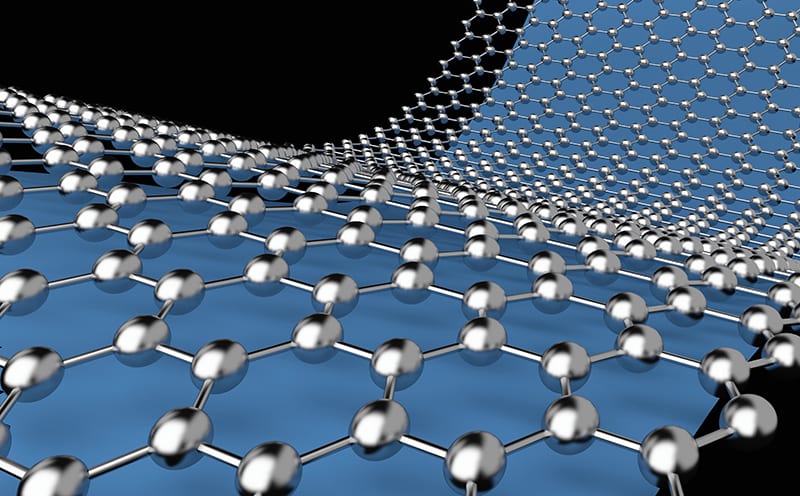

On a molecular level, Graphene, to be exact can disperse heat and resist corrosion. When paired with certain solvents, Graphene can strengthen and provide additional benefits to that solvent being paired with.

One of the best graphene coatings which have high durability and gives super-sleek finishing is Motoglanz Graphene Coating which is made in Germany.

SiO2 Coatings Vs Graphene. Comparisons & Similarities

With Graphene coatings, the water spotting and staining at less than 50% of traditional coatings is one of the claimed differences.

The other difference is their price in comparison to ceramic coatings. A 50ml bottle of Graphene coating can be found starting as low as 10,000 INR retail. This is as a result that 7 known solvents can suspend reduced graphene oxide. This makes it possible in some instances for Graphene coatings to be produced cheaper than SiO2 versions. For example, water is one of the carriers that can be used in a Graphene product. With an extremely small amount of rGO required, it brings the cost to produce a Graphene coating significantly lower than that of a Sio2 coating.